Factory Automation Systems is a trusted automation resource for many of America’s top manufacturers. Our automation solutions improve productivity, safety and quality while enabling our customers to maintain their systems with their internal skilled trades and engineering teams. These four technology groups – PLC’s, Drives, Information Systems, and Robotics – are the tools that FAS uses to build turnkey automation solutions.

Solutions and Technologies

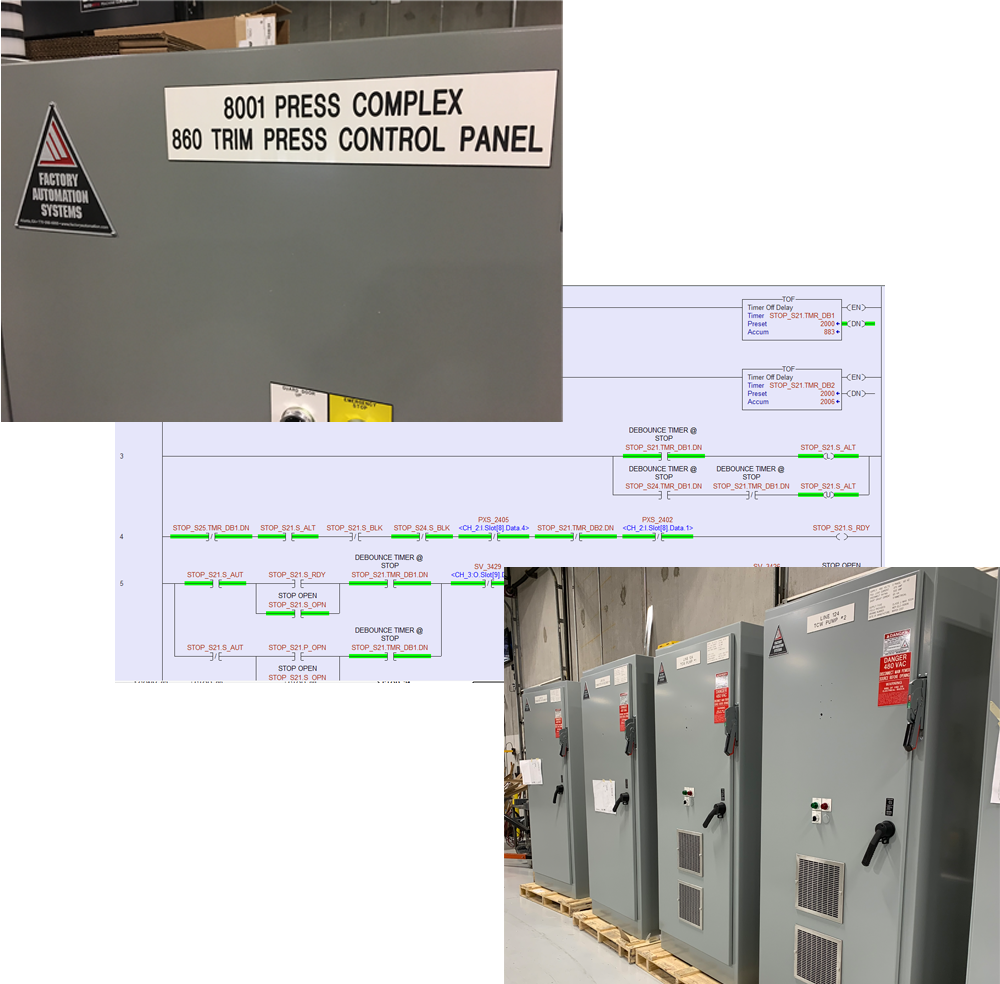

PLC Automation

With rare exception, a PLC is the cornerstone of each FAS project, with applications ranging from machine control, material handling, process control, machine safety to robot cell management. Our engineers are fluent in PLC’s, and our experience is measured in thousands of projects with PLC’s from Rockwell Automation, Siemens, and others. We offer panel fabrication, HMI’s, networking, machine vision, auto ID, and onsite commissioning services to round out our turnkey solutions.

New installations or retrofits – both are in our wheelhouse. For retrofits and upgrades, FAS works on outdated or underperforming control systems from third party companies. We also upgrade systems that our company installed 15, 20 or more years ago. We integrate systems that perform on day one and provide productivity gains for years.

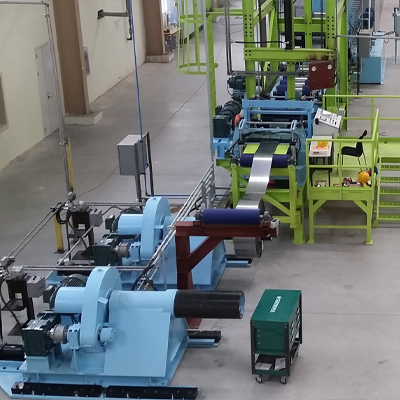

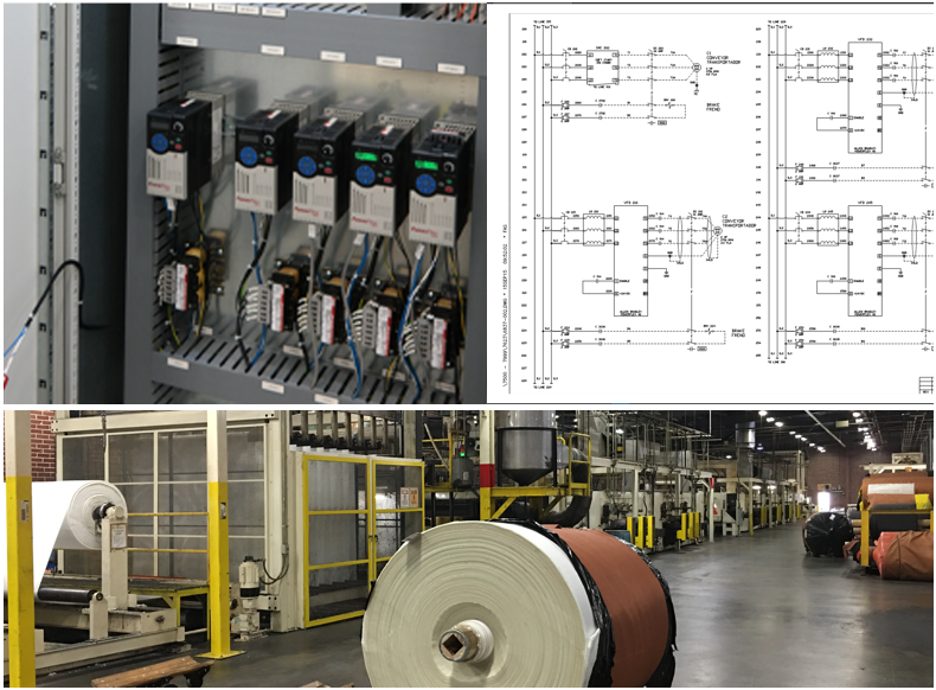

Motion Control & Drive Systems

FAS installs hundreds of axes of motion control each year, and our experience includes VFD’s, AC and DC coordinated drive systems, and servo controls. We implement material handling VFD’s, web handling, winders, printing presses, 50+ axes of coordinated servos, slitter positioning, and more. As with our PLC applications, we deliver numerous drives retrofits each year, updating obsolete technology and improving productivity.

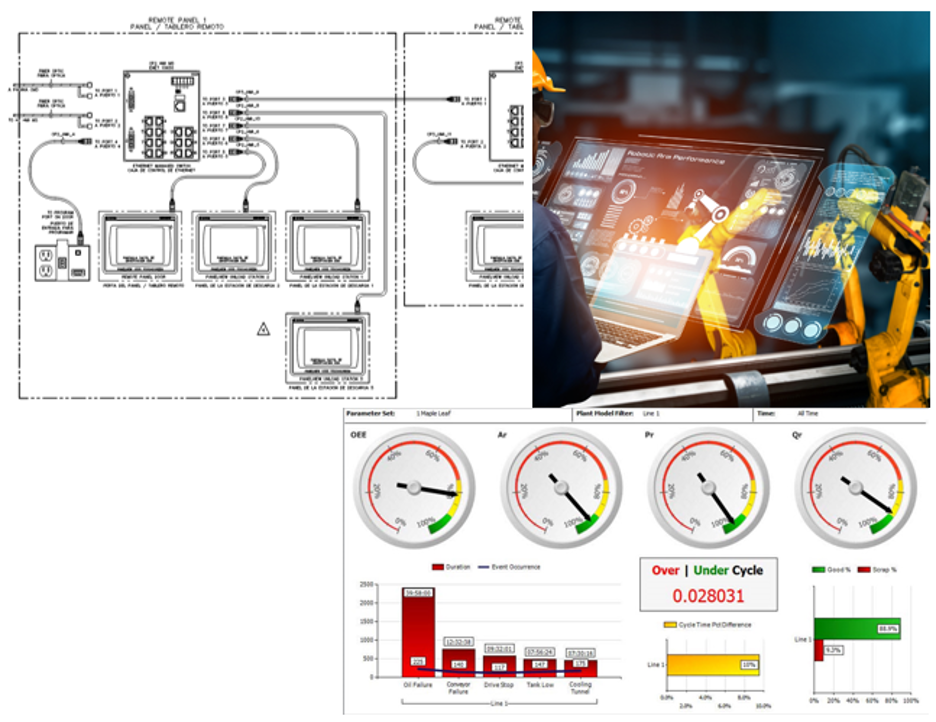

Information Systems

Turning manufacturing data into useful Information has been a core FAS capability since our very first project in 1992. Our application experience includes production monitoring, line coordination, traceability, routing & tracking and integration with plant business systems. We use software tools from Rockwell Automation, Inductive Automation, Wonderware, GE and Siemens, and we write custom code as needed. Our projects range from monitoring a single process up to plant-wide information solutions that are communicating with dozens of systems and collecting thousands of data points.

Robot Systems

As a turnkey robot integrator, FAS designs and implements robot cells in four primary application groups:

- Machine Tending

- Material Removal

- Assembly

- Material Handling/Case Packing/Palletizing

FAS has designed and deployed hundreds of machine tending applications, and our FlexTend™ processes leverage our past implementation practices to provide cost effective robot cells for Tier 1’s and other parts manufacturers. Material removal cells are becoming more prevalent as plants are looking for better finishes in less time and less direct labor. In the assembly and material handling categories, FAS implements robot-based solutions to automate processes that are not conducive to manual labor. Robotic case packing and palletizing are rapidly becoming the norm for high volume producers, and FAS has delivered a wide range of packing and palletizing cells.

Robot Systems

As a turnkey robot integrator, FAS designs and implements robot cells in four primary application groups:

- Machine Tending

- Material Removal

- Assembly

- Material Handling/Case Packing/Palletizing

FAS has designed and deployed hundreds of machine tending applications, and our FlexTend™ processes leverage our past implementation practices to provide cost effective robot cells for Tier 1’s and other parts manufacturers. Material removal cells are becoming more prevalent as plants are looking for better finishes in less time and less direct labor. In the assembly and material handling categories, FAS implements robot-based solutions to automate processes that are not conducive to manual labor. Robotic case packing and palletizing are rapidly becoming the norm for high volume producers, and FAS has delivered a wide range of packing and palletizing cells.

Assembly & Packaging

Material Removal

Material Handling

Assembly & Packaging

Material Removal

Material Handling

See more FAS robot videos on our YouTube channel:

OUR PARTNERS & KEY SUPPLIERS